1

Box production outside the packaging line

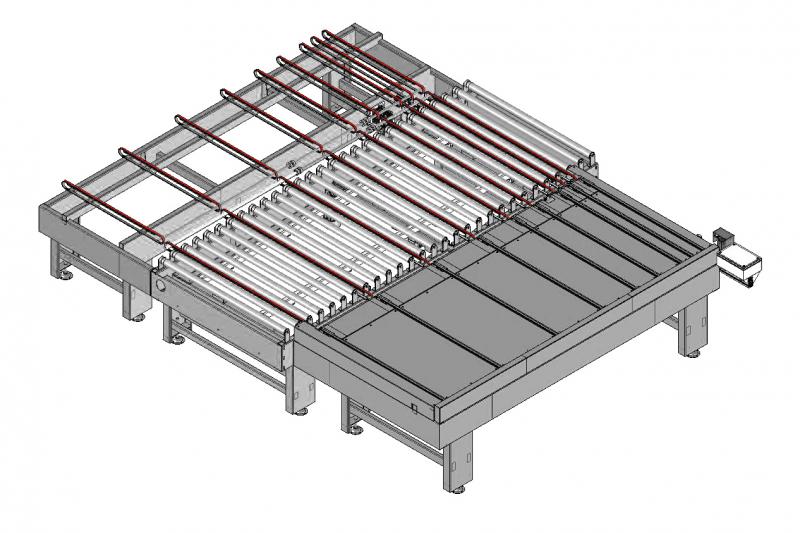

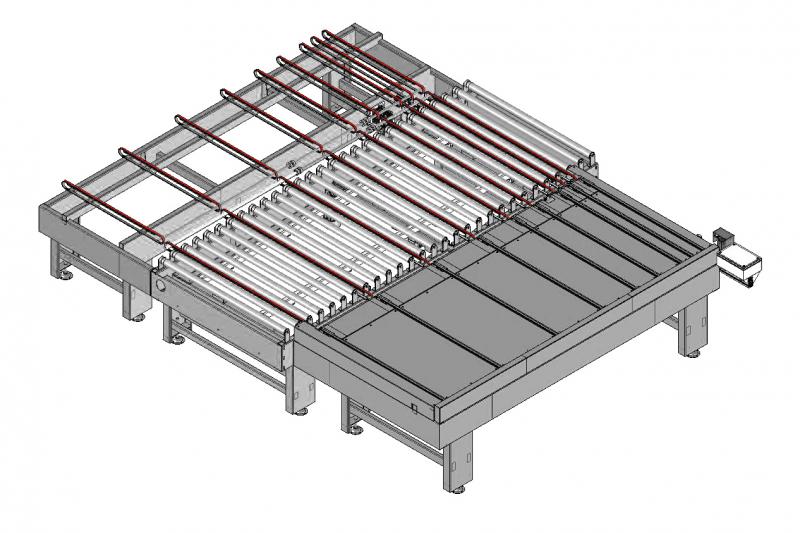

The system has been recently updated with a EVO packaging machine. The packaging machine features 6 fanfold slots in order to optimize fanfold consumption. By operating with 6 different fanfold widths, the machine is able to produce all the boxes within the dimensional range required by the customer.

2

Prep Stations

In order to achieve an output of 5 pcs/min, the system was equipped with 4 prep stations managed by 4 operators, which on average deliver approx. 5 prepared pieces per minute.

On the four prep workbenches, the operators form the box manually and position the products inside. The box is then transferred on a belt roller conveyor to the holding station so that the operator can prepare the next box.

From the holding station the box is then transferred to the main line according to the priorities assigned by the supervisor.

3

Box Closing Station

Once the boxes are introduced into the main flow, they are sent to the CM410S closing machine to be closed and glued with hotmelt glue.

4

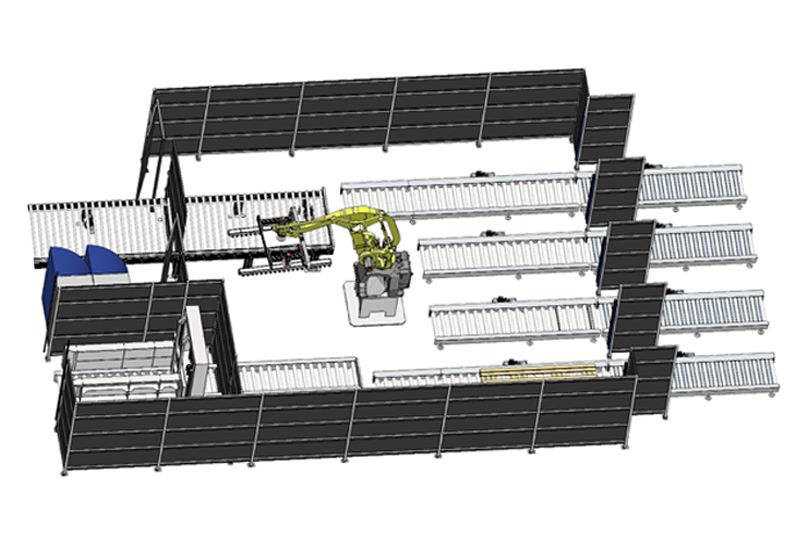

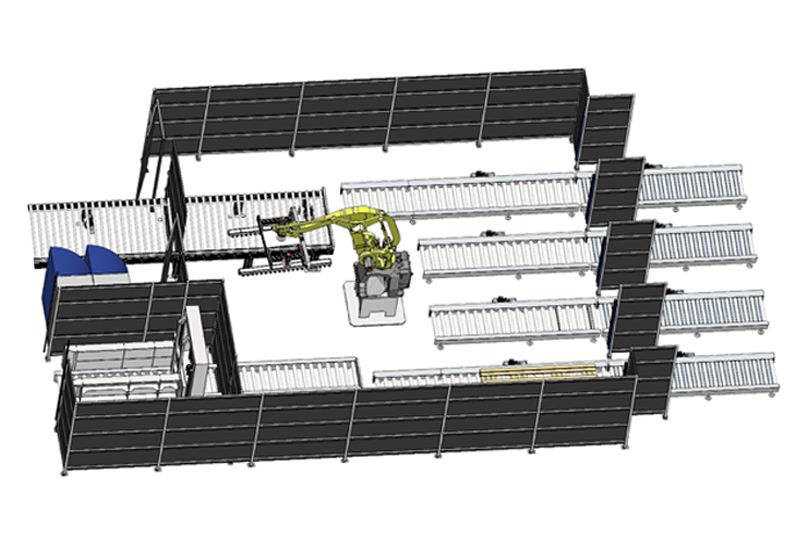

Palletizing

The palletizing area includes a Robot, a roller conveyor for the picking of empty pallets, a roller conveyor for the picking of the boxes and 4 palletizing stations.

The robot picks up the empty pallets from the roller conveyor and places them on each of the 4 palletizing stations. It picks up the boxes and places them on previously assigned pallet. Once the palletizing operations are completed, the pallet moves on to another roller conveyor until an automatic shuttle picks it up and the robot launches the next palletizing operation without any downtime in production.