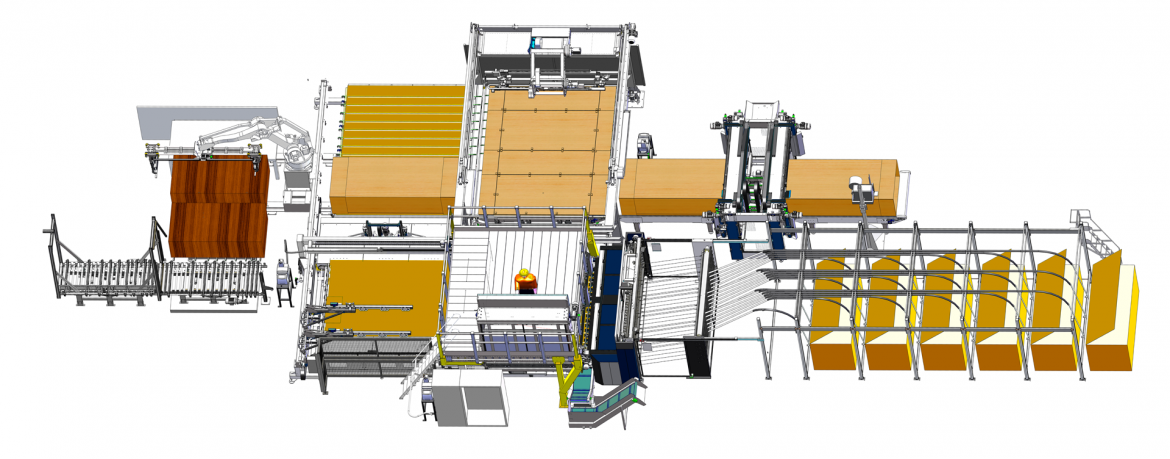

Box Design 201 and similar

This system was specifically designed to handle the boxes F201 or similar designs (e.g. 203, etc.): the traditional American boxes that are generally used to pack assembled furniture, such as kitchen bases and wall units, bedside tables, etc., or to ship goods in the e-commerce and logistics industry.

This type of system usually features a very high level of automation, since companies that choose to adopt this solution do so in order to automate the packaging process to the maximum possible extent, from producing the right sized box, to wrapping the box directly around the item(s), without involving an operator.