1

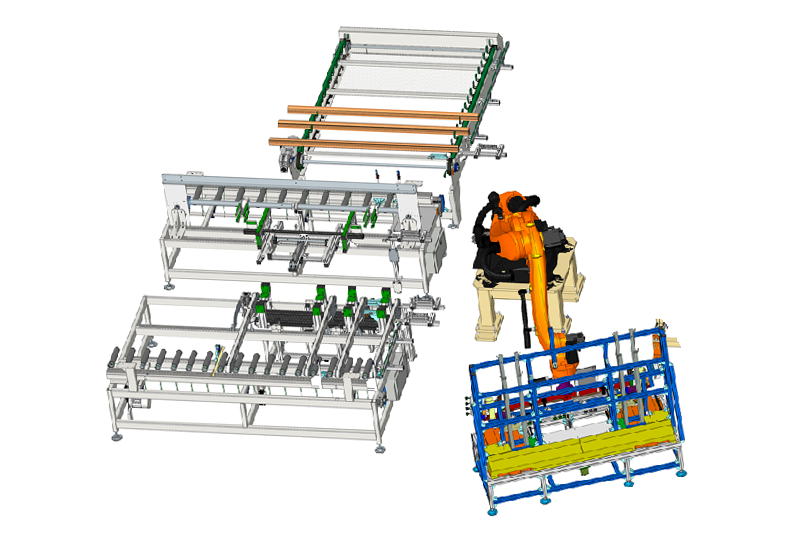

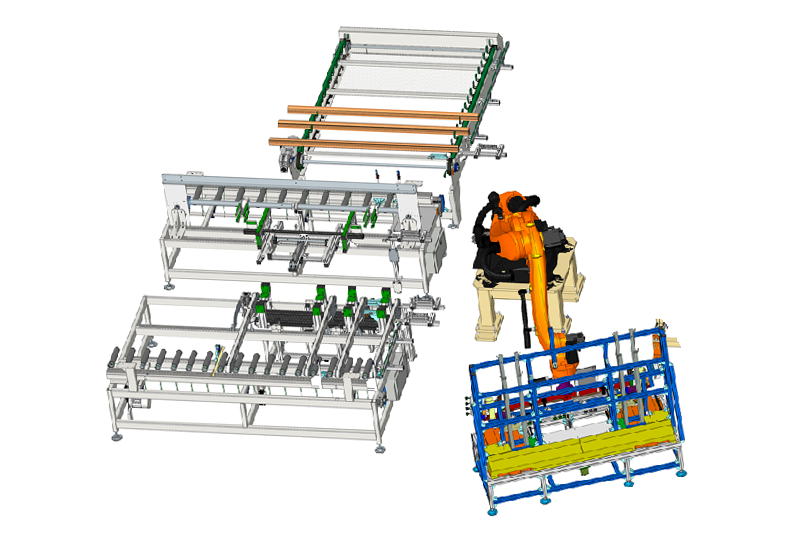

Item Prep Station

The system is provided with a first station to load the items, divided in two units: one unit loads the wooden profiles and the second one supplies the polyester protections.

The robot automatically picks up the wooden profiles first and then the protections.

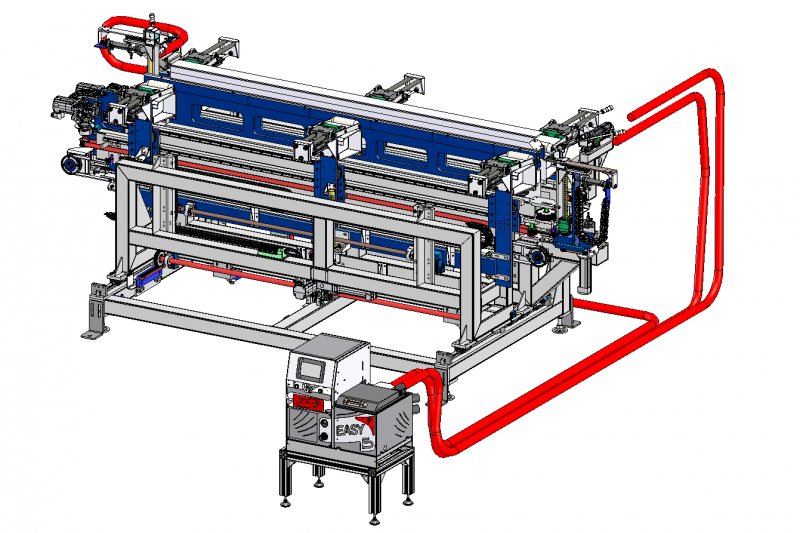

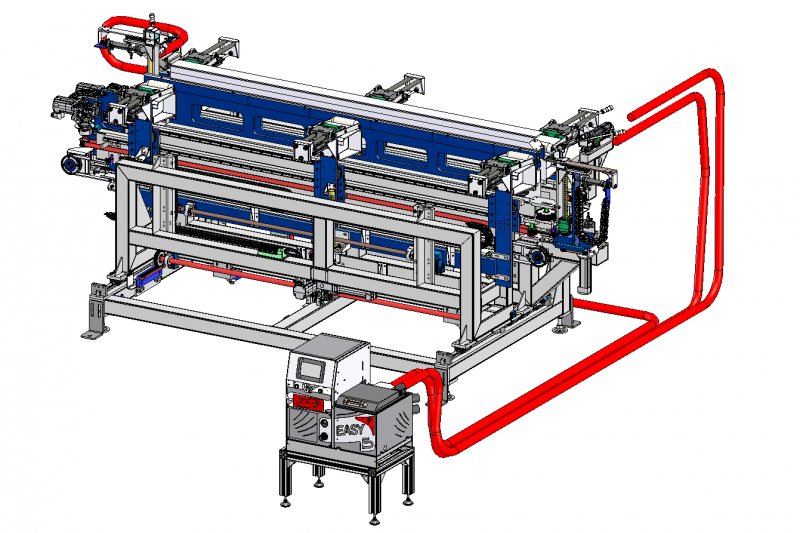

2

Box Procurement

The tailor-made boxes are produced by PANOTEC's high-end machine: EVO It is equipped with fanfold slots able to cover the whole dimensional range of the boxes required. At the outfeed of the packaging machine a conveyor automatically transfers the open box to the robot handling the box/item coupling operation.

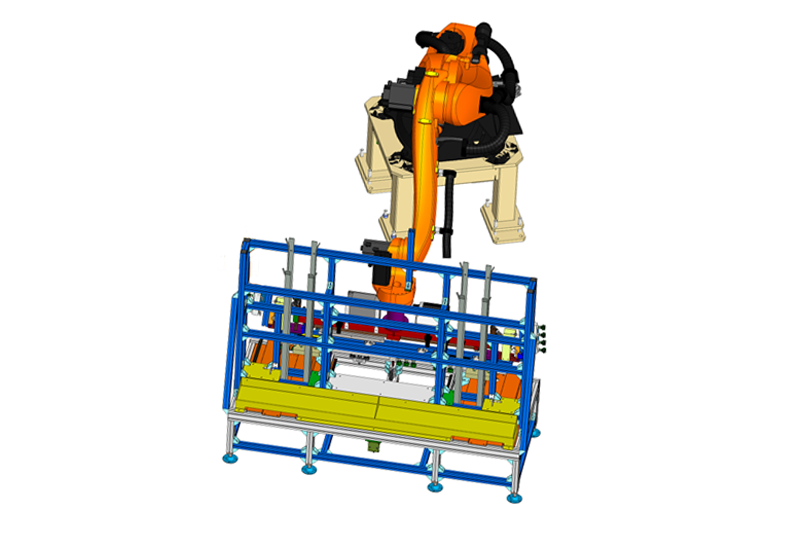

3

Coupling of Box & Item

The coupling and preparation of products are both fully automated.

The robot removes the open box produced by the packaging machine, and places it into the box forming station where the coupling operations will take place.

Once this operation is completed, the robot removes the profiles from the loading stations and stacks them on top of the open box. In addition to the wooden profiles, the robot also fits the polyester protections on top of the stack.

4

Box forming and closing

The coupling, forming and taping operations all take place at the same station. In the F401 unit, the sides of the box are erected, the side and top flaps are closed, and the box is conveyed through the automatic taping station.

5

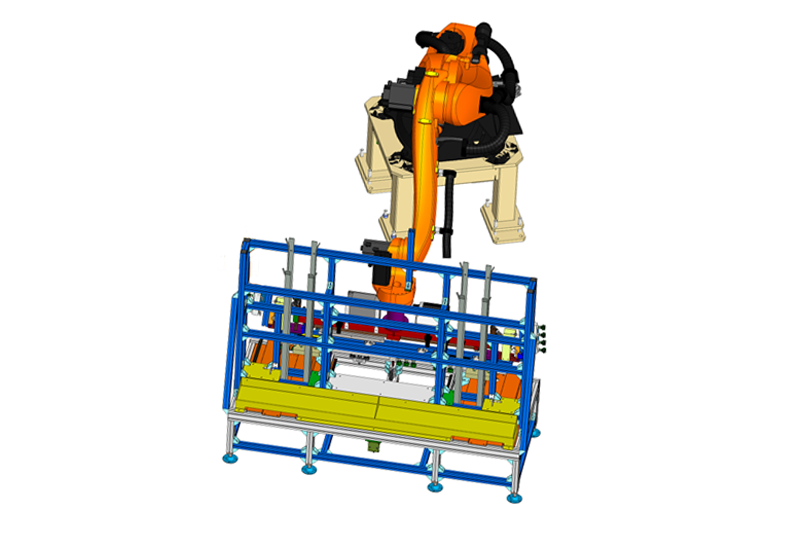

Palletizing

An automatic palletizing area equipped with a robot, a loading conveyor for empty pallets and a conveyor for the removal of the boxes completes the system.

The robot picks up the box and places it on top of the incoming pallet. Once the boxes are stacked and the pallet is ready, it is removed from the station by a conveyor.