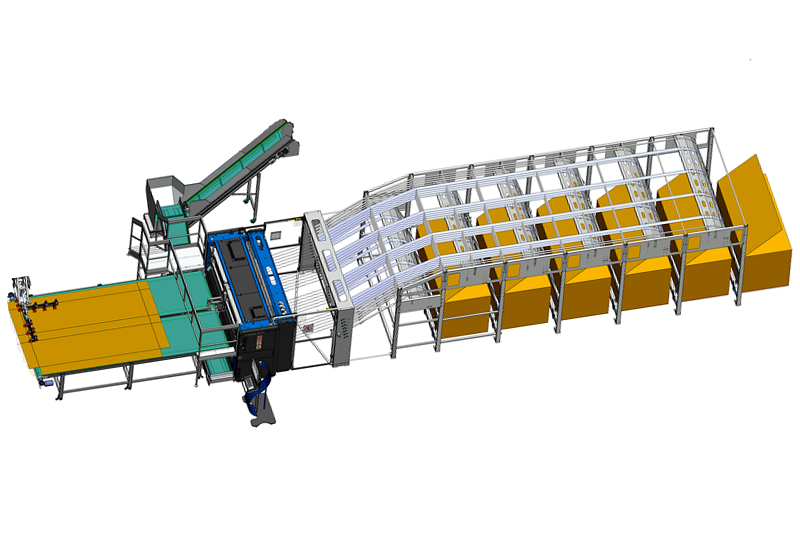

1

Box Procurement

The system features an Evo packaging machine equipped with 6 fanfold slots and a waste management system. The machine produces the tailor-made boxes afterwards processed by the packaging line

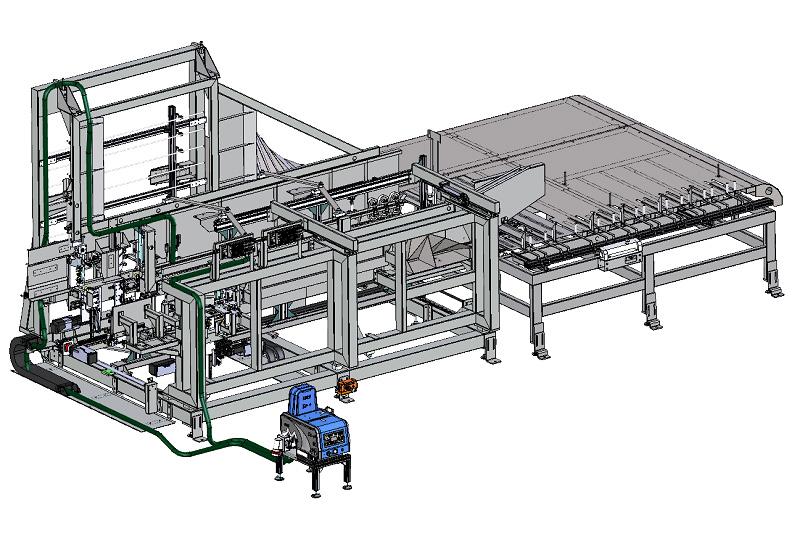

2

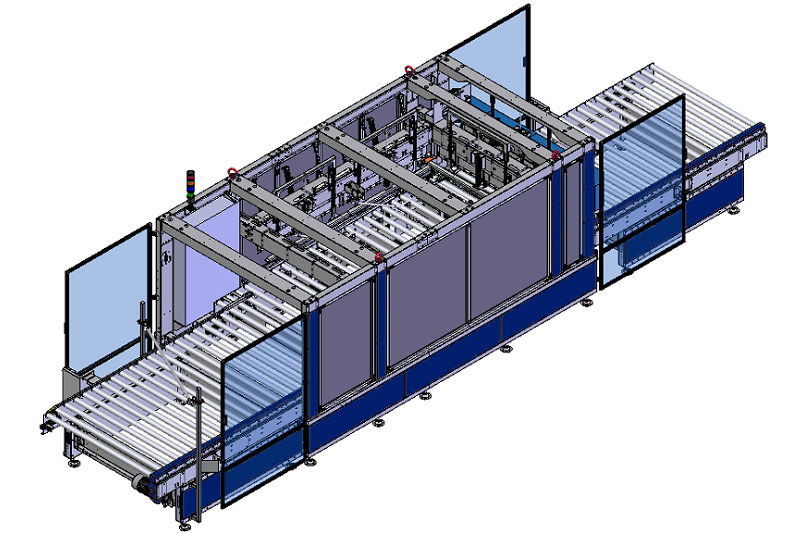

Box Handling Station

Once the box is produced, it is conveyed inside the FM410 using a cardboard handling system which completes the forming operations.

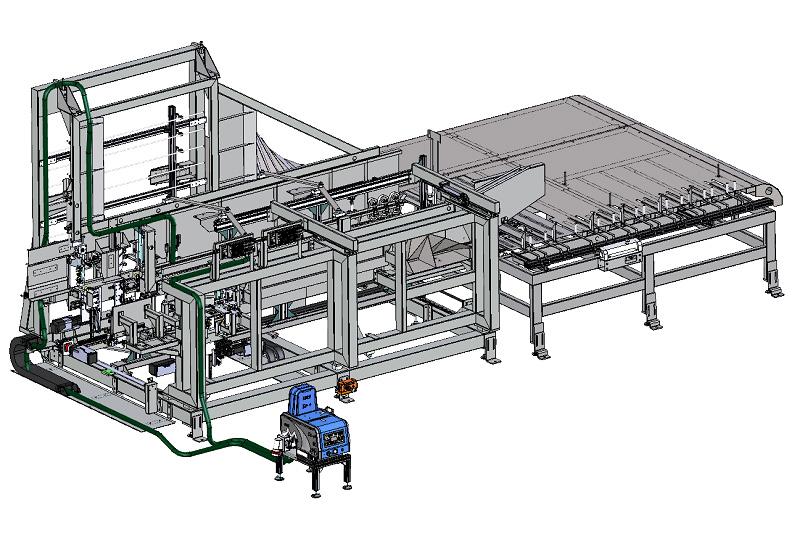

3

Forming Station FM410

The box is positioned on a centering device. A mechanical system aligns the box so that it enters the forming station correctly.

The special feature of this forming station is that it adjusts automatically to all sizes and therefore does not require any manual settings.

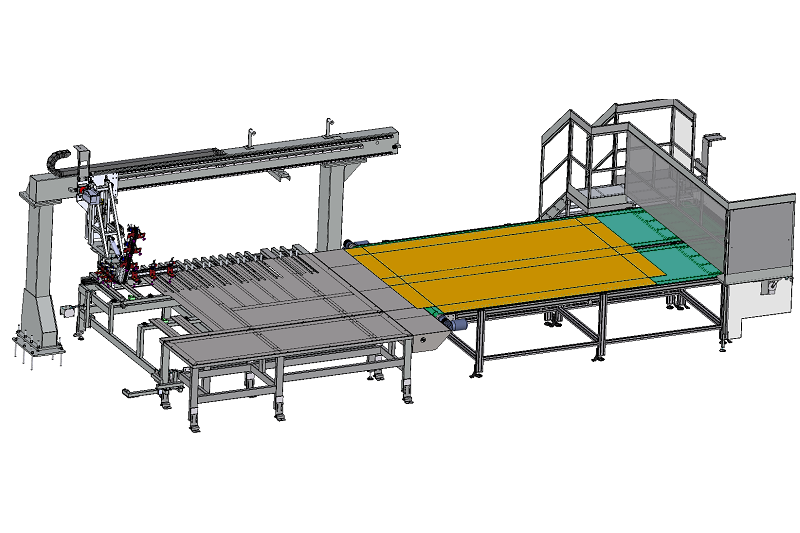

4

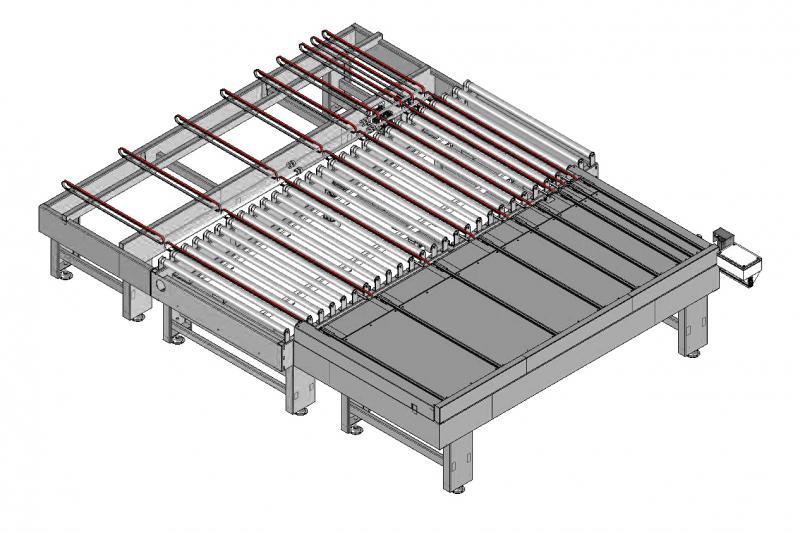

Prep Station

The system is provided with 3 prep stations: the operators position the items to be packed on trays and once the trays are ready, the operator releases the box onto the main roller conveyor directed to the CM410S box closing station.

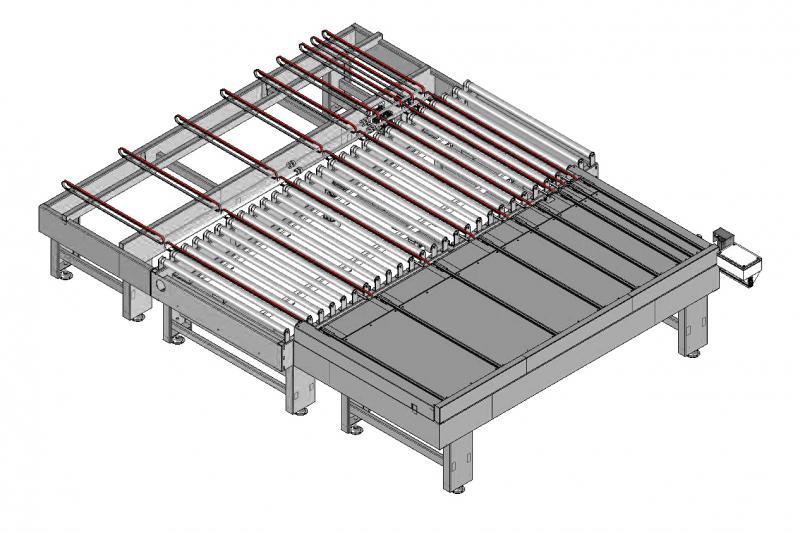

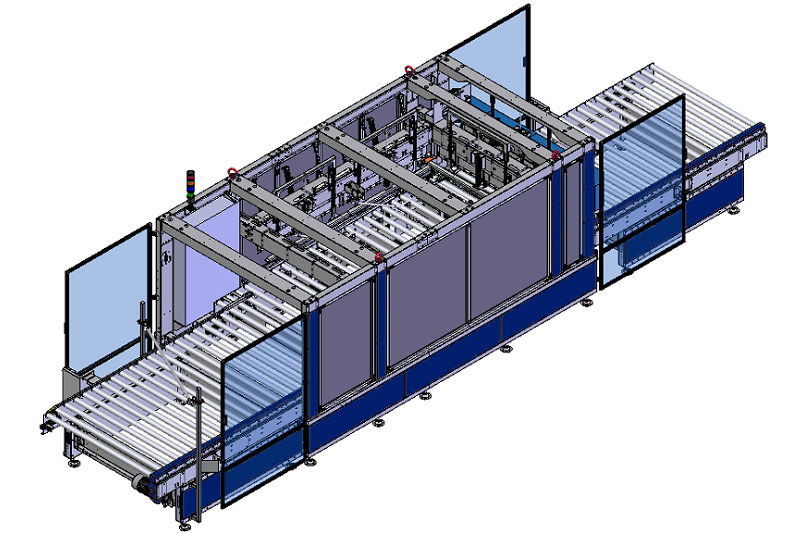

5

Closing Station CM410S

The boxes containing the items are then transferred to the CM410S closing station. The CM410S was designed to close boxes FEFCO 410. The longitudinal flap and the two transversal flaps are sealed with hotmelt glue. The properly sealed boxes exit the line and the station is ready to close the next boxes. So boxes of different sizes can be automatically closed one after another, NONSTOP.

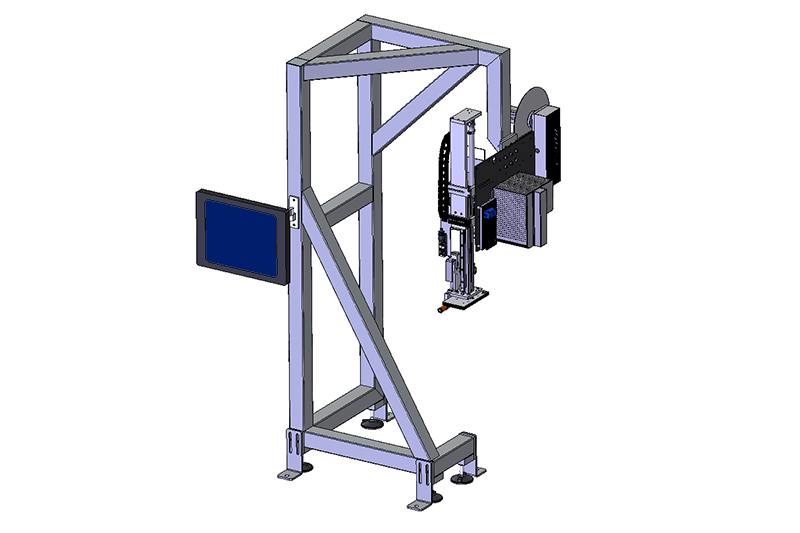

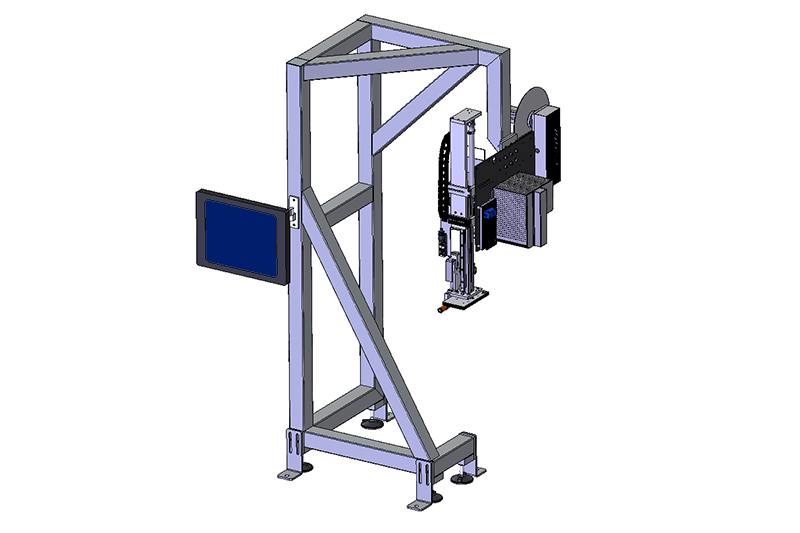

6

Labelling Station

Once the box is closed, a roller conveyor moves it to the labeling station. A device that automatically adjusts to all box sizes applies the label with all the relevant data on top and on the side of the box. The box is now ready to be transferred to the palettizing station.

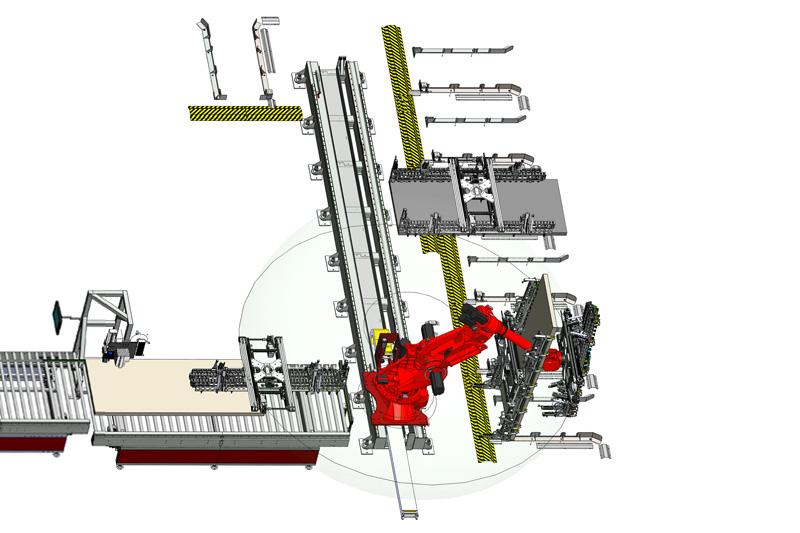

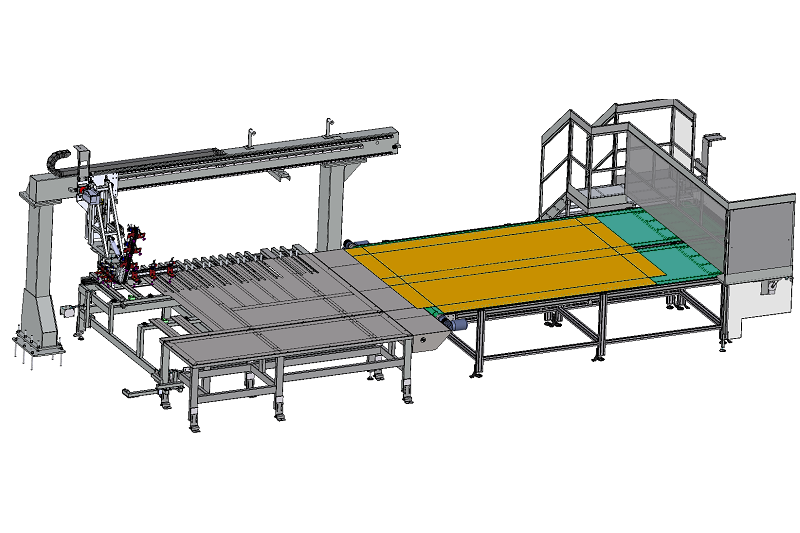

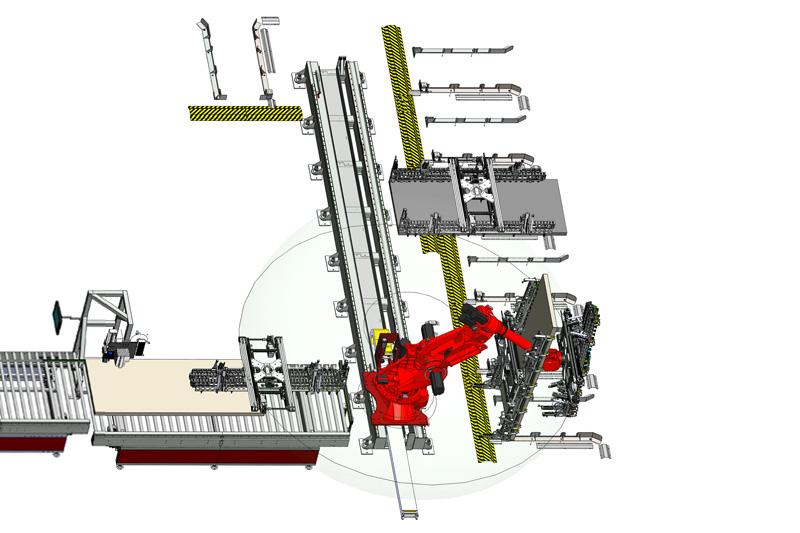

7

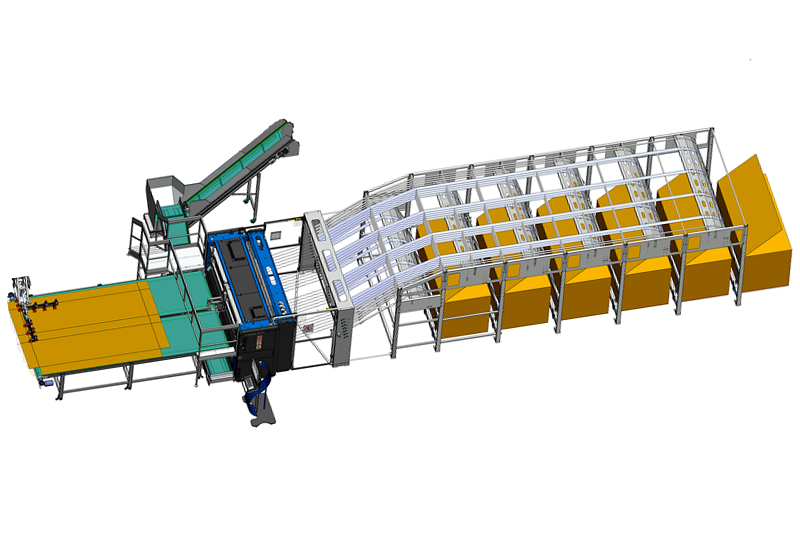

Palettizing Station

The 6-axis rail palletizing robot picks up the box from the picking area. Depending on the type of box, it can be arranged in a vertical position in one of the baskets or palletized in one of the two available roller conveyors. Once the boxes are in place, an operator clears the area via unloading gateways.